Hume Innovation

The Hume name in Concrete Casting- Walter Hume – Founder of the Hume Pipe Co. The Hume family has been working with concrete for four generations, over 100 years. The commercial history began with Walter Hume, a rare example of a self made entrepreneur who combined the qualities of inventor, promoter, manufacturer and large scale industrialist. At the age of 33 in 1909, he invented and developed the centrifugal process for manufacturing concrete pipe and in 1912 they cast the first concrete pipe using his patented process. The Australian Hume Pipe Co was formed in 1920 and expanded in the early 1920`s into New Zealand, Britain, South Africa, California and India. In 1922, Hume Industries (Far East) Ltd. was formed. During his lifetime Walter Hume took out more than 80 patents relating to concrete and steel pipe, welding techniques and numerous other engineering applications. In the 1930's, The Australian Hume Pipe Co was the only Australian company that exported Australian technology. The Hume Spun Process as it became known, was first applied successfully to the manufacture of round hollow concrete poles in Australia in the 1950`s to produce both stressed and non-stressed and is still accepted as world best practice.

Vertech Hume has been developing innovative technologies providing solutions for the power pole industry

64 – 66 Lock Avenue Werribee VIC Australia 3030 Telephone +61 3 9742 5277 Email tamas@vertechhume.com.au

Second Generation – Founders of W.R. Hume Pty Ltd. Immediately after WWII and following the death of Walter Hume in 1943, the four surviving sons established a new steel and concrete pipe company called W.R.Hume Pty. Ltd. This company made a significant contribution to the making and laying of pipe in Australia and was acquired by the Hume Co in 1959. The two companies became known as Humes Ltd. This second generation separately went on to establish a leading concrete post-tensioning company now listed as Structural Systems P/L.

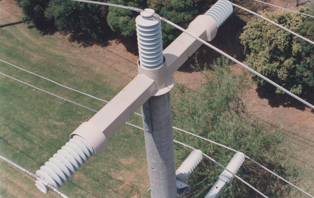

The Vertech Process. The Vertech Process was developed to manufacture concrete poles up to 14M for the distribution of power. The patented pole production process does not spin the mould, rather there is an inner core and an outer mould that when assembled creates a pole shaped chamber where a reinforcing cage is suspended. Concrete is pumped into the chamber and then compressed to extract any free water. The mould and core is removed immediately as the now stiff concrete adheres to the reinforcing cage.

The pole is steam cured to finish the process. The entire process is completed in 30 minutes.

Third Generation - Hume Bros. - The Casting of Polymer Concrete. For Don and Graeme Hume concrete, steel fabrication, quarrying and post tensioning is in their blood and it's given them a unique opportunity to use an innovative approach to all areas of analysis and problem solving. In the 1980's, their local electric power distribution network was experiencing bird flash over problems leading to bush fires. In response, Hume Bros invented a centrifugal polymer concrete casting system that produced an air free polymer concrete cross-arm cover that effectively solved these problems. The super profits generated by this polymer process funded all of the early development of the Vertech pole casting process.

Fourth Generation- Tamas Hume - The TransHume Process.

The TransHume process makes pre stressed concrete poles up to 30M for the transmission of power. The pole plant is a fully transportable low cost plant for localised manufacturing. The major benefits come from significantly reduced transportation costs.

The technology is scaled to meet local demand, relocating as required.